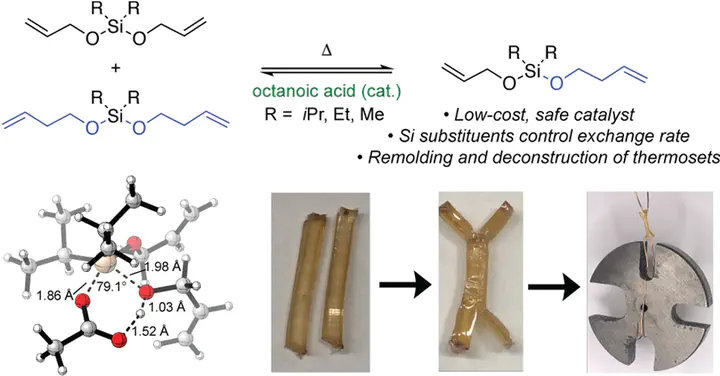

Remolding and Deconstruction of Industrial Thermosets via Carboxylic Acid-Catalyzed Bifunctional Silyl Ether Exchange

Abstract

Convenient strategies for the deconstruction and reprocessing of thermosets could improve the circularity of these materials, but most approaches developed to date do not involve established, high-performance engineering materials. Here, we show that bifunctional silyl ether, i.e., R′O–SiR2–OR′′, (BSE)-based comonomers generate covalent adaptable network analogues of the industrial thermoset polydicyclopentadiene (pDCPD) through a novel BSE exchange process facilitated by the low-cost food-safe catalyst octanoic acid. Experimental studies and density functional theory calculations suggest an exchange mechanism involving silyl ester intermediates with formation rates that strongly depend on the Si–R2 substituents. As a result, pDCPD thermosets manufactured with BSE comonomers display temperature- and time-dependent stress relaxation as a function of their substituents. Moreover, bulk remolding of pDCPD thermosets is enabled for the first time. Altogether, this work presents a new approach toward the installation of exchangeable bonds into commercial thermosets and establishes acid-catalyzed BSE exchange as a versatile addition to the toolbox of dynamic covalent chemistry.